Vero supports toolroom of the future

Vero supports toolroom of the future

Leading German tool maker Formenbau Kellermann GmbH reduced lead times by more than 20% after investing in VISI and installing a palletised production process with a zero-point clamping system.

The company, based close to Nürnberg was originally founded in 1970 by Mr. Heinz Kellermann and has become a sought-after partner to the automotive industry providing complex single- and multiple-component tools for high-quality plastic parts such as intake manifolds, oil modules, air filter housings and cylinder head covers. Having relocated and expanded twice, the company is now run by graduate engineer Ms. Sabine Kellermann and currently employs 27 personnel.

"Those who stand still have no chance in tool-making over the long-term. Automation has reduced our costs now and will continue to do so in the future.”

Sabine Kellermann

"Pricing pressure, competition from emerging countries and the trend towards ever shorter project terms are challenges that force tool manufacturers to rethink the classical form of single item production," explains Sabine Kellermann. "In tool-making, flexibility and the use of the latest technology is a must. This basic principle is also applicable to Formenbau Kellermann where we have invested heavily in machinery and software so we are ready to adapt to changing market conditions."

The milling and electrical discharge machining (EDM) departments are equipped with two HPM1350 U and HPM 1850 U 5-axis milling centres from Mikron/AgieCharmilles and one 5-axis Huron EX machine. In addition, there is a Mikron HSM 700 milling machine for electrode production, an AGIE 100 wire EDM machine, three vertical eroding machines (Exeron, Hansen) , as well as numerous manually operated machines for additional milling, drilling and grinding operations.

Automation

Process automation is a speciality of Formenbau Kellermann and this starts with the tool design. Areas which are not directly involved in the design, are also standardised to the greatest possible extent. Components such as pressure plates or guides are uniform in all tools. In the case of die centring, only two to three different sizes are used. In addition, there is an in-house company standard for design, as well as a standard component catalogue.

The CAD/CAM software of choice at Kellerman is VISI from British manufacturer VERO Software. "As a progressive company, we had already invested much earlier in 3D," explains Sabine Kellerman. "Prior to our switch to VISI in 2003, we worked with ICEM DDN, a product that had been on the market for many years but could no longer compete with modern systems."

Feature recognition drives CAM consolidation

In 2004, the NC department was equipped with VISI Machining where the CAM tasks were shared with PowerMILL from Delcam. However, in 2009 the company switched entirely to VISI for all machining activities. "The advantages of a uniform, consistent CAD/CAM system outweighed the benefits of dual products. Typically we deal with short programming times and feature recognition from native CAD data is an important component of our automation strategy," explains Sabine Kellermann.

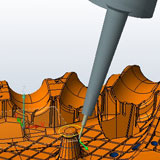

The introduction of 'Compass Technology' for feature recognition means that Kellermann automatically generate 2 and 2½-axis CNC programmes for regular geometries such as holes or milling grooves which are common features in tool making - dramatically reducing programming time and eliminating potential positioning errors. In principle, only three steps are necessary for CNC plate programming: Start the feature recognition, run the company-specific Compass based rules and finally, verification of the completed CAM programmes. The set-up and customisation of the Compass rules was performed by German VISI distributor MECADAT GmbH, where on-site assistance was provided to analyse the existing CAM strategies and transfer this knowledge to the rules database.

3-5 axis simultaneous milling

One function that is used intensively at Kellermann is the ability to automatically convert 3-axis to 5-axis continuous toolpaths. "This enables us to reduce expenditure on programming time and still benefit from the advantages of 5-axis machining," explains Sabine Kellermann. "For example, the Mikron HOM 1350U allows for an approach angle from +16° to -120°, whereby the distance between spindle and table is only 30mm. This approach is applicable for most geometries and we benefit from better surface finish through the use of shorter, more rigid tooling and reduced vibration."

Continuing, Sabine Kellermann says, "Automated and standardised processes also require the efficient supply of information. The possibility of sharing the tool library from VISI was an important milestone for our automated processes. For example, all tooling databases are available to all users across the network and contain information typically seen in expensive tool-management systems such as tool-holders, extensions, collets, cutting tools, including assemblies as well as their individual cutting conditions."

High machine capacity load - and still flexible

"There is rarely something that we cannot mill and we no longer experience bottlenecks on the CNC machines," says Ms. Kellermann. The 5-axis Mikron machining centres are equipped with a palette system that includes 3 round tables that can each be loaded with 1tonne and intelligent zero-point clamping systems which ensure highly optimised use of the CNC machinery. Sabine Kellermann also notes the flexibility advantages of a palletised and zero-point clamping system: "A running process can be interrupted at any time, without losing the zero-point. This can be particularly useful in case of urgent repairs, or when spotting surfaces must be quickly re-milled, all which effect lead-time and efficiency."

The benefits of the significantly improved process chain, software automation and advanced CNC machinery can all be verified in a recent project for the innovative air filter housing (inlet and outlet on the same side) for the new generation of diesel motors from Daimler (World Motor OM651) for the Mercedes E-Class Cabrio. With great pride, Sabine Kellermann concludes, "The consolidation of high-end software and high-end machinery has reduced our lead times by more than 20%. Those who stand still have no chance in tool-making over the long-term. Automation has reduced our costs now and will continue to do so in the future."

About The Company:

Name: Formenbau Kellermann GmbH

Benefits Achieved:

- Integrated CAD/CAM solution for design & manufacture

- Automated 2D machining using Compass Technology

- 20% increase in machining productivity

"Those who stand still have no chance in tool-making over the long-term. Automation has reduced our costs now and will continue to do so in the future.”

Sabine Kellermann